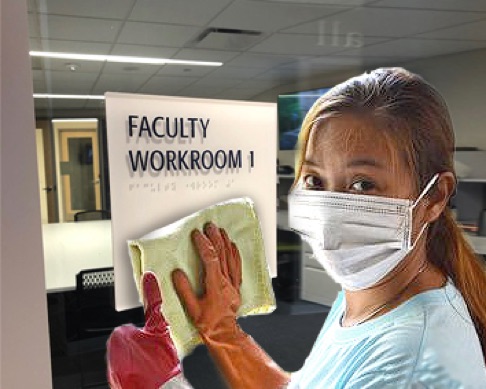

As we enter the “new normal,” which will mean keeping the environment as virus free as possible, we are faced with what to do about tactile and braille ADA signs. We invite people to touch them. Even people who have perfect vision find the signs at a convenient level to touch, and often, through curiosity alone, will touch them. Hospitals, clinics and nursing and care homes, schools and hotels — any facility with many doors to identify will be faced with the expense and knowledge needed to keep signs clean and virus free.

We can’t move the raised character and braille signs out of reach, but we can make them less apt to be touched by those who read visually, and when we do that, we can also make them much easier to clean and less susceptible to degradation.

ADA/SterilEaze™

The tactile sign system designed for the new pandemic era

• Easy to clean & sterilize

• Superior durability and chemical resistance

• More affordable than conventional sign systems

The answer is our thermoformed ADA/SterilEaze™ sign systems.

Thermoforming is the only method of making a true, one piece molded acrylic sign that is inexpensive enough to allow one of a kind signs with custom numbers and text. Unlike photopolymer, which is actually a hardened gel layer on a base, the signs cannot degrade when exposed to moisture. Many hospitals and clinics that wipe signs down daily already know what happens eventually to photopolymer signs after a few years.

What makes ADA/SterilEaze™ thermoformed signs less expensive both to manufacture and to clean, and actually easier to read by more people with vision based disabilities? We take advantage of a little-known section of the ADA standards and divide the signs into two parts, one visual and one tactile. The tactile sign is virtually invisible and does not invite touching. The visual sign can be much larger and easier to read and mounted higher on the door or wall, where touching is not a problem.

The tactile sign will remain in place where it’s easy to find and touch, but will be unobtrusive and have small characters with a rounded profile, no nooks and crannies to hide the virus. The signs can be quickly sprayed with alcohol or other disinfectant and allowed to drip dry. Ironically, these small, thin rounded profile characters are much easier for “touch readers” than the large bold characters that benefit visual readers.There will be no color or decoration on the smooth, solid surface of the sign. Most signs will be relatively inexpensive to make. There are no applied or layered characters to lose their edges and corners or braille dots to degrade or disappear with repeated cleaning. It’s a win-win situation, both for building management and its budget, for everyone who will benefit from the ability to clean the signs often, and for people with different levels of vision impairment who will gain a more readable system.

Thermoformed signs have become increasingly popular in the past several years as people begin to understand the many advantages. Now we see how easily they conform to the standards that allow us to completely separate visual and tactile corresponding messages and provide a better experience for visual and tactile readers. At the same time, you save time and money as we all respond to Covid 19 and the necessity for constant cleaning and sterilizing of the environment. H Toji and Company is delighted to reach its 66th year of providing architectural signage with the introduction of ADA/SterilEaze™ thermoformed ADA compliant signs.

Why Thermoformed Signs?